To lead your mission to success

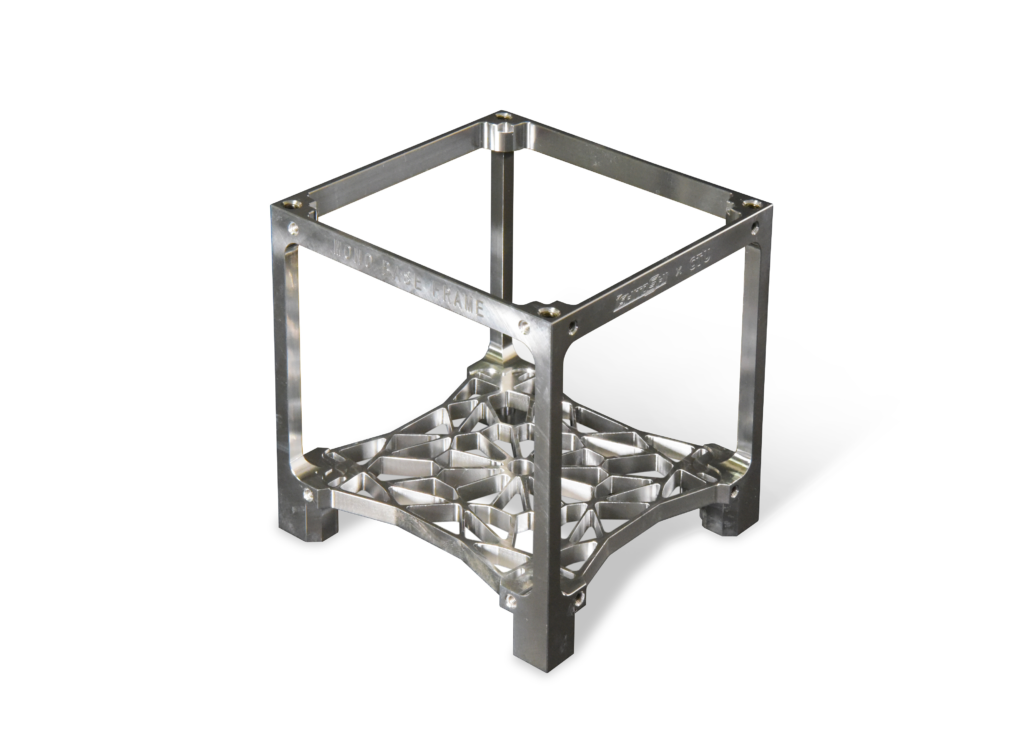

Ishitoshi Machining has developed a structure for the CubeSat technology: the “MBF-Mono Base Frame” The MBF is machined from a single aluminum block, creating a fully integrated, jointless structure. There are a number of reasons we machine from a single block.

Does it make it lighter?

Is it more rigid?

Is it easier to customize?

Yes to all, but none of them is the biggest reason.

If you were hand-building a single CubeSat and encountered a problem, of course you could rectify it. But could you assure consistent quality where the same modification had to be made in dozens of CubeSats?

The MBF’s external dimensions comply with the specifications defined in all existing Satellite Orbital Deployers. There is no need to make adjustments during installation, and similarly accurate results will be obtained regardless of the individual carrying out the installation.

In addition, the structure of the MBF is simple, minimizing concerns about interference between the mission device and the structure during design. As the MBF gains wider acceptance, mission devices and their components will be more and more subject to modularization, enabling an increase in the use of common parts and the associated efficiency.

The greatest advantage of the “MBF” being machined from a single block of aluminum is that accuracy is maintained regardless of who assembles it, allowing greater focus to be devoted to the design of the device rather than be consumed by the task of designing the structure, enhancing the likelihood of mission success.

We believe CubeSat frames are best machined from a single block of aluminum.Now some people we meet have similar ideas or have experience in single piece machining. But even they fear that this method of manufacturing is too costly, or too wasteful due to the large amount of swarf that machining creates, and so hesitate to use our CubeSat frames.

Let’s think about the first argument. Admittedly, the MBF that we developed are not cheap, compared with other frames made by our competitors. But we have managed to reduce costs of MBF manufacture by leveraging our experience manufacturing automobile parts.

The optimized machining process runs automatically at night reducing labor costs. We use a cutting-edge 5-axis machining center, which can machine multiple faces [or “perform multiple processes”] with the workpiece fixed to a single jig, dramatically reducing process time.

A number of other cost reduction were achieved in design, purchasing and testing.

MBF is one part, with one drawing, and we need purchase only one type of raw material.

MBF requires only one inspection, and the simple shape makes measurement easy, shortening testing time. As a result, we can offer our MBF at a price equivalent to our competitors’ products.

Therefore, it is NOT expensive!

Let’s now consider the second argument.

It is true that the machining swarf is a waste, one needs to be aware that there are many advantages to this approach. Do you want the problem of highly sensitive assembly work using torque wrenches and so on? The MBF can reduce the total number of bolted joints, where you will not have to worry about bolts becoming loose as a result of vibration during launch. It is important to note that anyone can achieve stable accuracy, as no adjustment is required. Assembly personnel will require less training than a satellite specialist. Given the above gains, is it still to be regarded as a waste?

The external dimensions of our MBF at delivery comply with CubeSat specifications, and the dimensional and geometric tolerances required for the MBF to operate smoothly inside the Satellite Orbital Deployer, do not exceed one third of the tolerance specification. For example, the parallelism of the part, which is specified to be within 0.2 mm is actually 0.05mm. If you use our MBF, you will not have to worry about the accuracy of the structure.

We accept a full-order of one MBF, where the product is designed from scratch.

In that case, we charge design fees to cover meetings to finalize specifications. However the design can be modified rapidly using CAD and machining can start immediately without the need for tooling such a dies and jigs because all we are doing is changing the amount of aluminum to machine, and its final form.

The standard delivery time for a full-order is three weeks from finalization of design.

If you are unsure about how to machine the material into the shape you want, or frustrated that you are unable to customize the existing products, please contact us.

We can make your ideas come true. We may be able to overcome issues that your satellite is currently facing, with our machining technology.

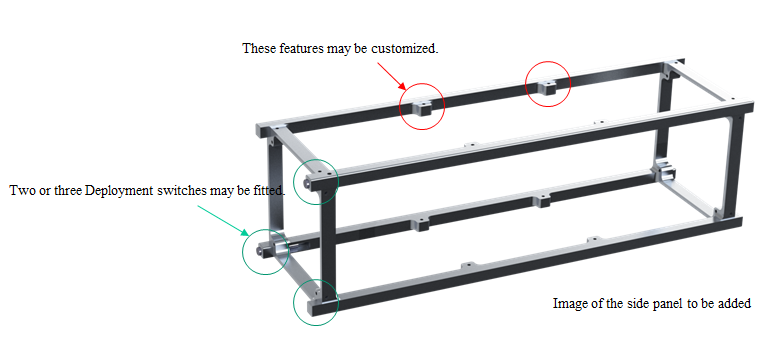

If your priority is to reduce the costs, we recommend that you begin with a semi-order. We would normally supply the MBF complete with side panels for a semi-order.

We can attach brackets to fix circuit boards or cameras by machining holes on the side panels, without changing the basic structure of the standard MBF.

In addition you can easily carry out additional machining of the side panels yourself. The standard delivery time for a semi-order is two weeks.

We can install deployment switches which can detect the satellite being deployed from the Satellite Orbital Deployer into the space, onto the MBF and side panels.

This switch performs the important task of waking your sleeping satellite at the time of launch. If it fails to wake the satellite, it will be no more than a box floating in space. The deployment switch mechanism actually relies on technology derived from the molding of Japanese roof tiles.

Japanese roof tiles are cast in molds and a valve in the mold – operated by a combination of air pressure and spring – bleeds any gas that would otherwise prevent the correct forming of the tile. The sliding operation of these valves relies on very high precision machining of the sort in which we excel. The design of the deployment switch is based on this gas release valve mechanism. The actuating pin is stainless steel, and slides in and out turning the power on and off. We strive to ensure the perfect functioning of your satellite.

The “mono” of MBF (=Mono Base Frame) has two different meanings in Japanese: “single” and a “thing”.

We believe that the MBF will not only serve as a platform for CubeSat, but also become the basic frame for many other things. For example, could it be used as a frame for a custom installation unit, where a specific function could be easily added to a larger satellite with minimal impact on the satellite’s design?

A laboratory unit to utilize the space inside the frame

A web camera for space, a private telescope unit only for users who purchase the access rights to operate as they like.

A unit to fall from orbit after completing the satellite’s mission in order to avoid becoming space debris

A telescopic arm unit using two or more frames.

We wonder if it could be used not just in the field of aerospace, but also for drones for business use, which must be light weight and rigid, or even for flying cars.

Our vision for this product is by no means limited to the CubeSat format.